Casati Flock&Fibers

The Flock Technology

Certified Innovation

How does the flock production works?

Discover how the flock creation process comes to life in our Renate facility, utilizing industrial machinery and specialized systems designed for grinding, cutting, dyeing, and activate the flock powder.

PHASE 1

Raw Material Procurement

Textile raw materials are selected based on the fiber type (vegetable, animal, synthetic, artificial) and its physical presentation (tow, staple, or textile scraps) for flock production.

PHASE 2

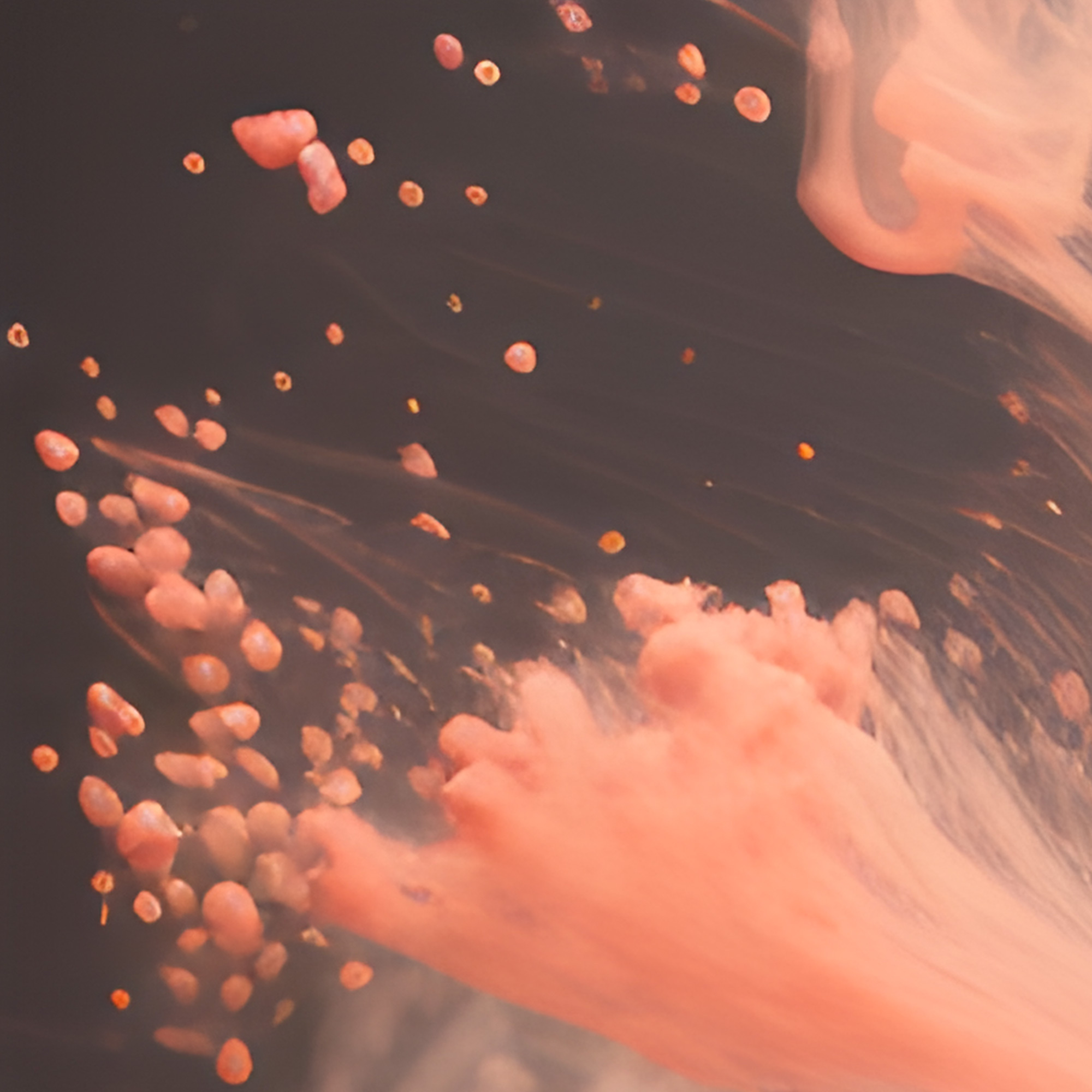

Grinding (staple and textile scraps)

Raw materials in the form of staple or textile scraps, not being continuous bundles, undergo grinding through industrial mills, resulting in flock powders with various granulometries.

PHASE 2

Cutting (tow)

Raw materials presented as tow (a continuous ribbon of multiple filaments joined) are cut using guillotine cutters, ensuring precise measurements for the subsequent process.

PHASE 3

Dyeing

Flock powders, whether from grinding or cutting, undergo the dyeing process in dedicated vats, meeting specific customer requests in terms of color and fiber fastness.

PHASE 4

Activation

In the dyeing vats, the flock undergoes activation through a chemical recipe, creating a "film" around the fiber and making it suitable for flocking machines.

PHASE 5

Drying

After the dyeing, activation, and centrifugation processes, the flock powder passes through dryers, where it is dried with hot air.

PHASE 6

Sieving

This procedure eliminates longer textile fibers that may be present within each individual production.

PHASE 7

Flock

The flock, properly bagged, is ready for shipment.

Quality Control

Casati Flock&Fibers is committed to monitoring and ensuring high product quality throughout all stages of the process through numerous tests.

- Precision cutting control

- Micronage control of fibers

- Laboratory color control with the reference sample

- Possible final color correction

- Verification of the presence of longer fibers (their presence would create craters in flocking)

- Checking the "hand" of the flock, assessing the softness of the flock

- Checking the conductivity of the flock, the effectiveness of the flock's activation.

- Simulation of flocking to evaluate the workability of the flock in flocking plants.

- Ensures that the flock does not release color when rubbed, both in wet and dry conditions.

- Typically measured in a few seconds, determining the correct fiber penetration time into the adhesive used for flocking.

- The rise time simulates the duration it takes for the flock fibers to fall down from the net to the flocking surface.

- Verification to check if the flock fibers are separated from each other, to ensure good flowability for them to fall from the machine’s net in the right way.

INDUSTRIES

Flock is an extremely versatile semi-finished product, making it applicable across various industrial sectors. In the same industry, flock can be employed for highly technical purposes and simultaneously for more glamorous applications.

- Velvet-effect flocked fabrics with total or partial flock prints for clothing and furnishings

- Flock transfer for fabrics

- Blankets

- Curtains

- Blackout curtains

- Coated with filler

- Coating with filler

- Flocked outer packaging

- Flocked foam rubber

- Packaging coatings with interior fibers

- Flocked paper

- Recycled paper created from textile waste

- Decorative paper

- Wallpaper

- Flocked design objects for special effects

- 3D printing with recycled fibers

- Flocked fabrics for sofas or armchairs

- Flocked furniture for special effects

- Flocked wallpaper

- Flocked doormats

- Flocked hangers

- Flocked objects or toys

- 3D printing with recycled fibers

- Flocked swabs for medical analyses

- Flocked applicators for lipstick

- Cosmetic sponges

- Brushes

- Flocked outer packaging for special effects

- Provide reinforcement and inhibit cracking

- Flocked sound-absorbing products

- Filler for sound insulation

- Filler for thermal insulation

- Fibrous concrete

- Fibers increase tensile strength, impact resistance, deformability, crack resistance

- Primers and finishes

- Decorative coatings and paints

- Stabilizers for paints

- Filter papers

- Felts

- Optimizes dimensional stability and porosity of the filter medium

- Technical absorbent or abrasive articles

- Sponges

- Cloths

- Flocked rubber profiles

- Flocked window seals

- Flocked glove box

- Door panels

- Carpets

- Flocked thread

- Battery reinforcement Increased safety for brake pads

- Grass for dioramas

- Sand for dioramas

- Flocked objects

- Flocked objects

- Flock powder

- Flocked flowers

- Flocked branches

- Fake natural snow

- Snow-covered

- Christmas trees Snow-covered

- Christmas objects

- Velvet-effect flocked Christmas baubles

- Banknotes

- Passports

- Certificates

- Stamps

- Masterbatch from recycled fibers

- Natural fiber fillers for bioplastics

- Slip and heat regulation for thermosetting materials

- Recycled flock for glamour applications

- Recycled fibers for technical applications

APPLICATIONS

WHAT ARE THE APPLICATIONS OF FLOCK?

Explore the versatility of our flock, a semi-finished product adaptable to a wide range of industrial sectors. From technical contexts to glamourous ones, flock offers innovative solutions for every application.

HOW DO FLOCK APPLICATIONS TAKE PLACE?

Flock applications take place thanks to the flocking process, a technological production process through which flock powder is applied to a surface, flat or three-dimensional, previously covered with adhesive.

WHAT ABOUT TECHNICAL FIBERS?

The applications of technical fibers, on the other hand, do not involve the flocking process, since these are almost always used as fillers, and therefore inserted directly into the compounds.

has sound-absorbing properties,

making it ideal for various

sound control applications?

you can contribute to circular economy

projects by creating your flock

from textile waste.

applicator tips are made using flock?

are flocked for an elegant and soft touch on one side,

and to reduce noise and vibrations

from objects on the other?

can be used in paper as a filler

for structure or as a dye?

are used in cement to provide

more structure to the material?

can contain ground fibers

from pre-consumer fashion waste?

are integrated into money for

anti-counterfeiting purposes?

in concrete

prevents the formation of cracks?

prevents clothes from slipping?

Christmas tree is made of flock?